Automatic feeding, printing, drying and collecting, saving labor

and overcome the constraints of weather conditions.

Pressure equalization and thick ink layer, adapt to the printing of

high-grade non-woven products.

Various size of screen frame plate is available.

Multiple patterns can be printed simultaneously when do large

format printing, which is largely improved the work efficiency.

Minimum effective pattern printing gap low to 10mm before and after

full-pattern printing, largely reduce the material consumption.

The driving of the whole machine and chromatograph systems adopts

servo motor control, ensure the printing precision.

Printing position is accurate and stable. It can be used together

with transverse cutting, slitting and non-woven bag making machine,

which is largely improved the production efficiency.

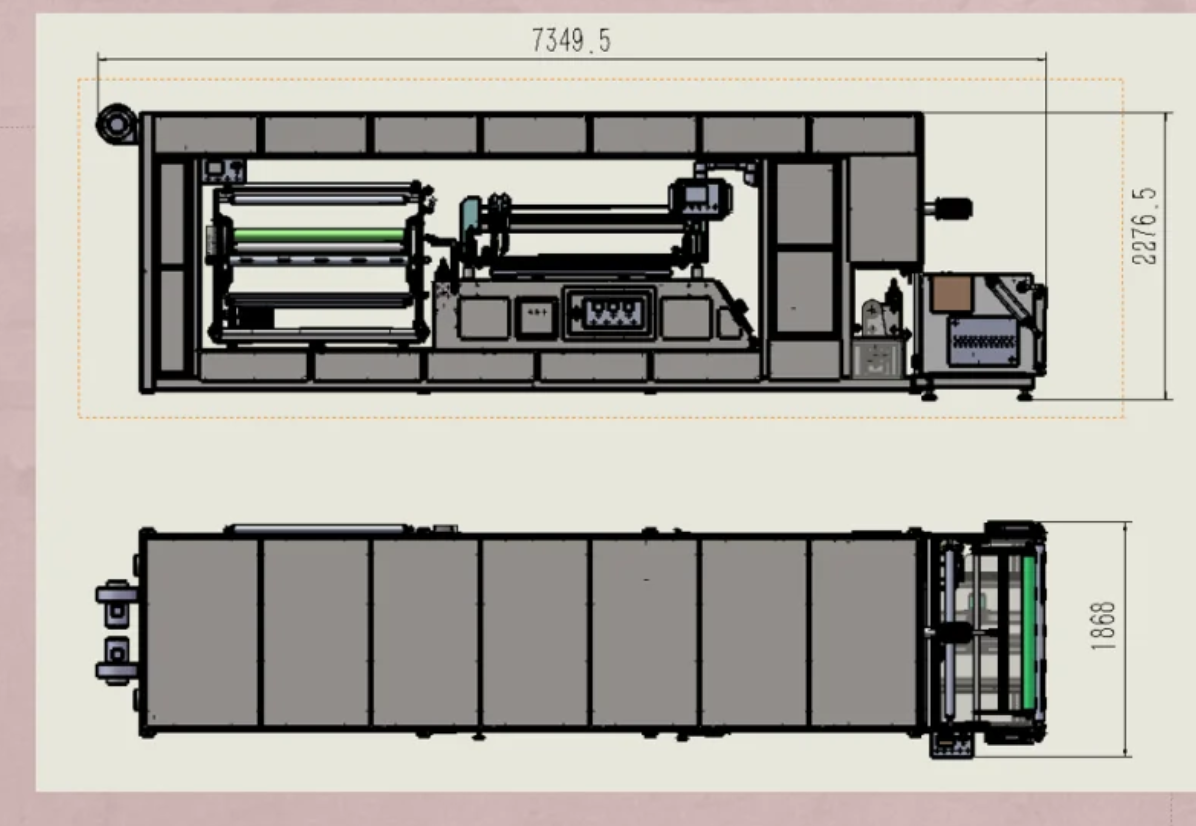

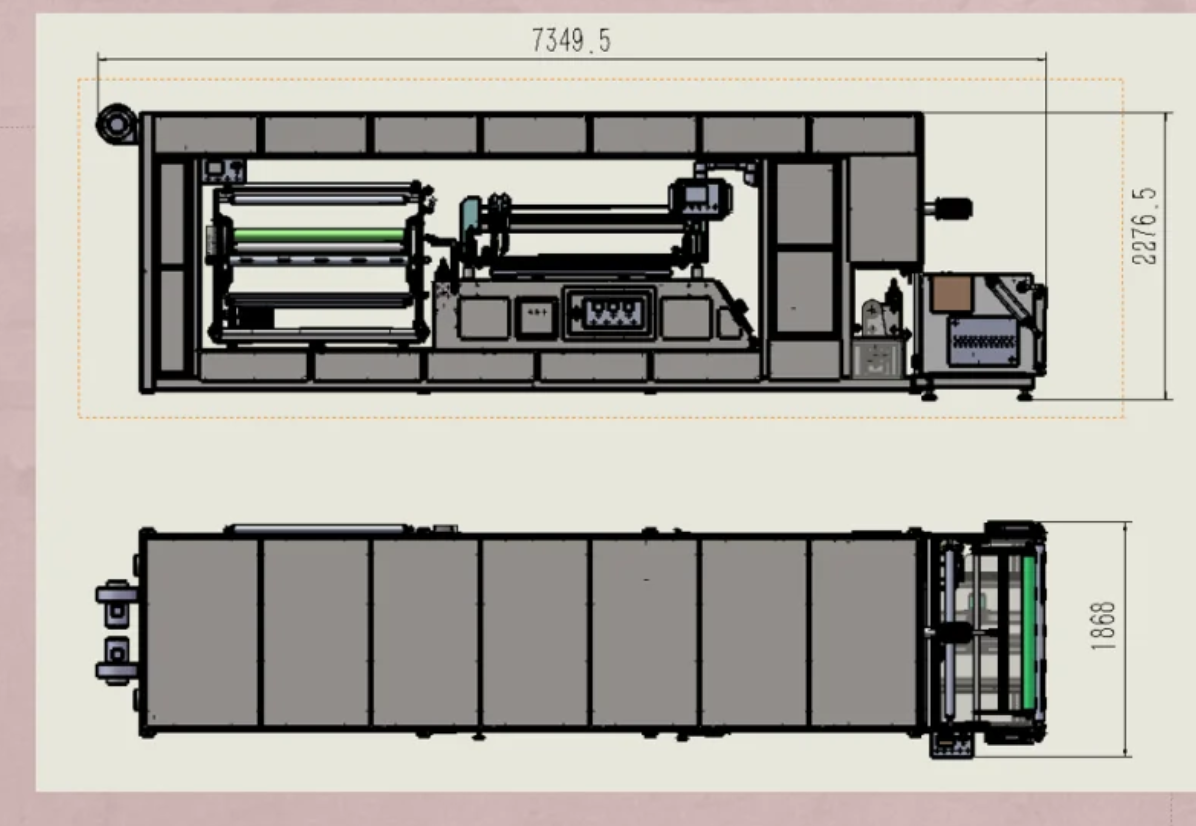

Specification

Model | XDP-A1200 | If you have different requirements, please let us know, and we will

provide you with customized solutions based on the actual |

situation of the machine. |

|

|

|

|

|

|

Material | Rolls of pp spunbond noven fabric |

|

Production speed | 500-1200meter/hour |

|

Fabric thickness | 45-158gsm |

|

Width of Feeding Material Roll | 1250mm |

|

Max Diameter of Material Roll | 1000mm |

|

Max Printing Size | 1300*1200mm |

|

Power supplier | 380V |

|

Total Power | 15KW/380V |

|

Overall dimension (L*W*H) | 7500*1800*2200mm |

|

Weight | 4200KG |

|

Pressure requirements: 0.8-1.0 Mpa (recommended 7.5KW screw air

compressor with refrigerate air dryer and 0.6 m3air tank) |

The principle of an Automatic Color Screen Printing Machine

involves the following steps:

Substrate Preparation: The substrate, such as fabric, plastic, or paper, is prepared and

mounted onto the printing platform or conveyor belt of the machine.

Ink Preparation: The ink is prepared and loaded into the printing system.

Different colors are typically stored in separate ink reservoirs or

chambers.

Screen Preparation: Screens with stenciled designs corresponding to each color layer

are set up in the printing station. Each screen represents one

color in the final design.

Printing Process: The substrate moves through the printing stations, where the

screens are brought into contact with the substrate surface. A

squeegee blade or roller applies pressure to force ink through the

open areas of the stencil onto the substrate, transferring the

desired design.

Color Layering: For multicolor designs, the substrate passes through multiple

printing stations, with each station applying a different color

layer onto the substrate. Registration systems ensure precise

alignment of each color layer to create a cohesive and accurate

final design.

Drying/Curing: After printing, the substrate may pass through a drying or curing

station, depending on the type of ink used. Heat, air drying, or UV

curing methods are employed to dry and fix the ink onto the

substrate surface, ensuring durability and color fastness.

Quality Control: Throughout the printing process, quality control measures are

implemented to monitor print quality, color accuracy, and

registration alignment. Any defects or inconsistencies are

identified and addressed promptly to maintain printing integrity.

Finished Product: Once printing is complete and the ink is fully cured, the

substrate is inspected, trimmed, and prepared for further

processing or packaging. The final printed products exhibit vibrant

colors, precise designs, and consistent quality, ready for

distribution or use.

FAQ :

1. who are we?

We are factory ,based in Guangdong, China.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

paper cup machine,nonwoven bag making machine,nonwoven printing

machine,plastic bag making machine,Side Sealing machine

4. why should you buy from us not from other suppliers?

We provide high quality goods at lowest price.